I finally got a 3D printer this month. The prices have come way down for the Fused deposition modeling (FDM) - type printers. I picked mine up for just short of around $200 usd. Now, don't get me wrong it was not a good piece of equipment out of the box. The power supply broke after just a few turns so I had to use an old 600w PC PSU which I charge my lipo batteries with.

The heating element (hotend?) also wasn't up to much to begin with as it seemed to leak, or clog up and require stripping, cleaning burning with a blow torch, and reassembling then recalibrating every fricking time it decided to break. in the first two weeks it had a serious clogging problem roughly 2 out of three print jobs. But eventually, I learned to adapt the hotend, stop the clogs, stop the leaks, and optimise the printer settings. Things such as layer height, infill density, print speed, retraction, hotend temperature, fan speed, all these things I have learned can affect the print quality or success/failure.

I'm still sticking with PLA material because I do not have a heated bed yet, so I'm not using ABS just now. There are new materials appearing all the time now too. Materials such as a flexible ninjaflex, or a wood mix such as bamboofill, woodfill , and corkfill, there are many types of material described here & here if you have more interest in what they are and what they do.

I have been learning to use Repetier Host software to create printable files from 3d model files. I'm altogether happy with how it performs and it feels like a good all-in-one solution for hobby printers.

I am also using a free version of Sketchup to make 3d designs quickly and *fairly accurately*. It has its own imperfections and several frustrations, however the learning curve was not as steep as I have experienced with 3d design software in the past (such as Blender & Lightwave eesh). I feel sketchup allows me to make simple geometric designs suitable for my simple FDM printer. I want practical objects that I either cannot buy in the shops, or that I can make more cheaply and more quickly.

I am limited to a small print diameter of 180mm, but I can print as high as 300mm depending on the model.

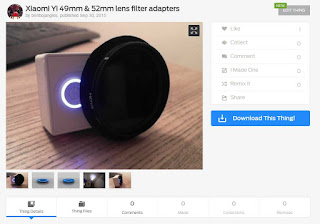

I have been designing things like I said earlier, for those objects that I can't buy in the stores yet, or which I could make more cheaply and quickly; and I have been posting these objects on my user page at Thingiverse. I'm not affiliating with any of these services or products by the way, it's just what I have used to get me printing. My designs are free to use for all, and not for commercial use or profit which I feel is a fair notion as we can now see on the internet, Chinese vendors who are now selling other people's designs ready made. I figure that once you put something onto the internet it is not secure and it becomes a wild west environment hey-ho.

I'm altogether happy with the printer now. It has taken work and has been frustrating at times but from general knowledge and practice it has worked and I'm producing new designs from the thoughts in my head, every few days, and that can't be a bad thing at all, in fact I'm quite taken by how the mind changes with regard to product and our understanding of it. We can so easily just think of an idea and create it, and it will be unique to your thoughts and requirements.

I whole heartedly recommend investing in a pair of measuring callipers

That is all right now.

Please feel free to ask me any questions or advice, and also please offer your tips.

2 comments:

I love your blog! I have been following your progress with the FLYSKY i6 mod for a few weeks now and noticed that you have a similar 3d printer to me. I tried to upgrade the hot end in order to improve the printer, but it seems to make it worse than before. I hope I can get mine working as well as yours.

I too upgraded/tested different hotends. My original one regularly oozed pla. I recommend experimenting with different nozzle shapes (same 0.4mm hole though). I also recommend upgrading the bowden extruder to get a better 'bite' on the pla material being pushed towards the extruder. Thanks for reading my blog :)

Post a Comment